-

01

Highly adaptive

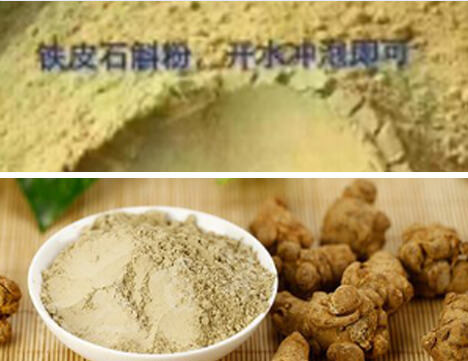

It is suitable for any fibrous material, high toughness material and high viscosity material: the roots, stems, leaves, and flowers of plants; cereals; condiments; non-metallic materials; mineral materials with Mohs hardness below 6.5; chemical materials; additives; all other materials that need ultrafine grinding can achieve ideal grinding effect.

-

02

Fineness adjustable

Series A: adjustable within 100-300 mesh;

Series B: adjustable within 300-1000 mesh;

Series C: adjustable within 1000-6000 mesh.

-

03

Unlimited moisture content of materials

All sundried, air-dried, kiln dried or freeze-dried materials (except fresh materials) may be crushed. The crushing effect is not affected even if damp or wet. Materials with high sugar content (such as Chinese wolfberry, Chinese-date, etc.) should be kiln dried before being crushed.

-

04

Unlimited feeding size

Roots, stems, leaves and block materials may be directly crushed in the machine without the need of coarse crushing, and powdered at one time. Mineral materials need to be coarsely crushed before they can be pulverized in the machine.

-

05

Screening rate:100%.

Efficiency of fragmentation:100%. -

06

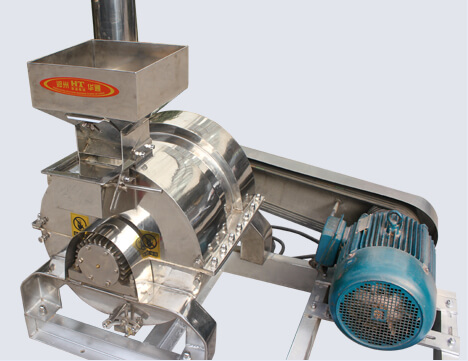

Core technology of Huatong ultrafine grinder

Grinders of numerous manufacturers have been suffering such a problem: fineness will become large and unstable with the wear of wearing parts. The core technology of our ultrafine grinder is that fineness remains constant and stable in the case of wear of wearing parts.

-

07

Performance comparison of Huatong ultrafine grinder

Huatong ultrafine grinder is the only ultrafine grinding equipment with high cost performance that can achieve high fineness and continuous mass production in the field of ultrafine grinding in China.

It has solved the problems of adopting jet mill for making ultra-fine powder, such as high price, large power, more supporting facilities, difficulty in maintenance, low fineness for fiber materials including Traditional Chinese medicine, and low production. It has solved the problems of high energy consumption and high price of gas grinding to pulverize chemical materials and mineral materials.

It has solved the problem that mass production is unavailable for vibratory crusher.

-

08

Low-temperature crushing

With low-temperature crushing function, it can work 24 hours a day.

-

09

Assembly line production

Continuous feeding and discharging ensures the color and efficacy of the materials, and prevent the loss of active ingredients. The machine can be operated independently or fully automated in the production line.

-

10

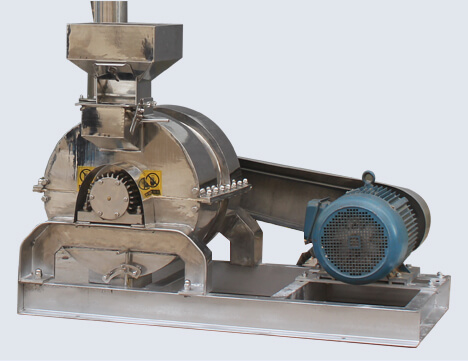

Anti-clogging function

The main engine is designed with anti-clogging function to avoid crash.

(In case of material blockage in production, the blockage can be eliminated without stopping the machine.)

-

11

Cleaning function

Due to the large number of materials, each part of the main machine is designed with a cleaning opening, which is easy to disassemble (assemble), replace materials, and clean. It can be cleaned and disinfected with water, compressed air and alcohol.

-

12

Features

No sieve, no residue (all crushed, 100% utilization rate of materials), no circulation (powdered at one time, high efficiency), no vibration, small volume, no foundation, not fixed, easy to move, convenient to be put in the upstairs.

-

13

Environmental protection

The crushing process is completely closed without dust pollution, making the operating environment clean and environmental friendly.

-

14

Operation

It is easy to operate and repair with low maintenance ratio. Only one person is needed for operation and maintenance, without the need of professional mechanical maintenance personnel.

-

15

Service life

It has long service life, no discarding period.