Fineness adjustable within

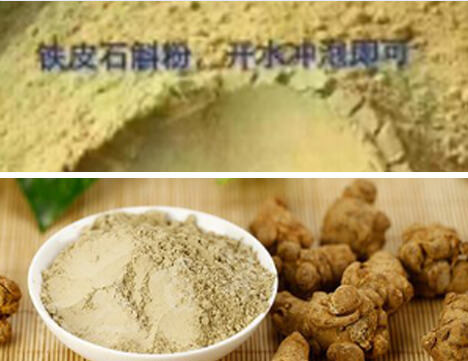

It is suitable for all kinds of chemical materials, additives, pigments, non-metallic materials, and mineral materials, etc.

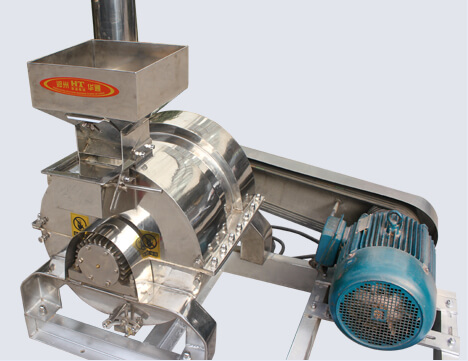

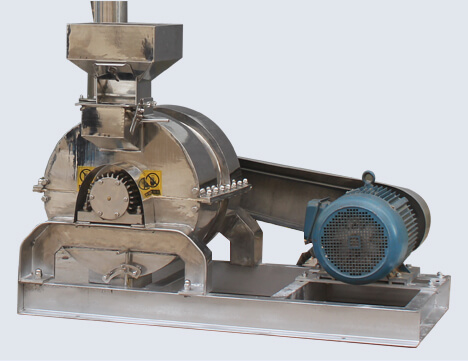

It uses the blade cutting and the high-speed air impact, and can complete the particle pulverization and particle sorting at the same time. In the process of blade cutting and grinding, the rotor produces high-speed airflow which rotates with the cutting direction of the blade, and the materials accelerate in the airflow. The repeated impact makes the materials receive double crushing at the same time to accelerate the crushing of the materials. The crushed materials enter the grading chamber with the airflow.

Due to the high-speed rotation of the grading rotor, the particles are affected by both the centrifugal force generated by the grading rotor and the centripetal force generated by the viscous action of the airflow. When the centrifugal force received by the particles is greater than the centripetal force, the fine particles below the grading size will be collected into the powder collector with the airflow, and the gas will be automatically discharged by the dust collector. As a kind of new high technology combination equipment, it has a performance superior to the airflow grinder and mechanical grinder, which can replace the imported equipment.

It is characterized by low energy consumption, short process, small area, no dust pollution, small heat generation, fine particle size of finished products, wide crushing range, unlimited water content of materials, unlimited particle size of feed, etc.

It is suitable for any fibrous material, high toughness material and high viscosity material: the roots, stems, leaves, and flowers of plants; cereals; condiments; non-metallic materials; mineral materials with Mohs hardness below 6.5; chemical materials; additives; all other materials that need ultrafine grinding can achieve ideal grinding effect.

For all kinds of plant roots, stems, leaves, flowers and other materials required to break cell walls, the efficiency of fragmentation is 100%.

Grinding requirements suitable for 100-6000 mesh: series A: fineness adjustable within 100-300 mesh; series B: fineness adjustable within 300-1000 mesh; series C: fineness adjustable within 1000-6000 mesh.

Grinding at room temperature or low temperature ultra-fine grinding can be adopted.

The jacket of the grinding cylinder is fed into the cooling water, and the grinding temperature can be controlled by adjusting the temperature of the cooling water.

Grinding is conducted at low temperature, refrigeration temperature up to -35°C (low temperature configuration).

All parts of the machine are made of stainless steel, which is the universal material of international medicine and food machinery.

It is easy to disassemble (assemble), clean and refuel, and can be cleaned and disinfected with water, compressed air, alcohol and steam.

Pollution-free: the crushing process is completely closed, without dust pollution, which fully improves the working environment, no loss of crushed materials and their active ingredients.

The equipment has been calibrated to balance, no vibration, which greatly reduces the noise of equipment.

In the process of material crushing, Huatong ultrafine grinder is multi-purpose, suitable for ultrafine grinding of all kinds of plant, mineral, chemical, non-metallic materials; grains, seasonings, bran, tea; shavings, wood chips, bamboo, etc. It is environmentally friendly and pollution-free, reducing the burden of cleaning equipment.

Complete discharge of materials in the device shall be ensured. With complete models, it is suitable for different production needs. Each part of the machine can be disassembled for cleaning.

The inside and outside of the machine shall be smooth. The pipes in the machine or device in contact with the material shall be sanitized. The length of each section shall not exceed 2 meters, and there shall be quick coupling meeting the requirements.

| Model | HT-400(A.B.C) | HT-500(A.B.C) | HT-700(A.B.C) | HT-800(A.B.C) | Description | |

| Power (KW) | Two-pole-11KW | Two-pole-15KW | Two-pole-22KW | Two-pole-30KW | The properties, specific gravity and fineness of the materials are different, so are the yields. According to the fineness requirements, series A, B, C products may be used. | |

| Speed | 4015 | 3262 | 2900 | 2900 | ||

| Fineness (mesh) |

A;100-300(mesh) B;300-1000(mesh) C;1000-6000(mesh) |

A;100-300(mesh) B;300-1000(mesh) C;1000-6000(mesh) |

A;100-300(mesh) B;300-1000(mesh) C;1000-6000(mesh) |

A;100-300(mesh) B;300-1000(mesh) C;1000-6000(mesh) |

||

| Moisture content | Unlimited | Unlimited | Unlimited | Unlimited | ||

|

Mineral materials (Mohs hardness below 6.5) |

<5mm | <5mm | <5mm | <5mm | ||

| Moisture content | Unlimited | Unlimited | Unlimited | Unlimited | ||

It is suitable for any fibrous material, high toughness material and high viscosity material: the roots, stems, leaves, and flowers of plants; cereals; condiments; non-metallic materials; mineral materials with Mohs hardness below 6.5; chemical materials; additives; all other materials that need ultrafine grinding can achieve ideal grinding effect.

Series A: adjustable within 100-300 mesh;

Series B: adjustable within 300-1000 mesh;

Series C: adjustable within 1000-6000 mesh.

All sundried, air-dried, kiln dried or freeze-dried materials (except fresh materials) may be crushed. The crushing effect is not affected even if damp or wet. Materials with high sugar content (such as Chinese wolfberry, Chinese-date, etc.) should be kiln dried before being crushed.

Roots, stems, leaves and block materials may be directly crushed in the machine without the need of coarse crushing, and powdered at one time. Mineral materials need to be coarsely crushed before they can be pulverized in the machine.

Grinders of numerous manufacturers have been suffering such a problem: fineness will become large and unstable with the wear of wearing parts. The core technology of our ultrafine grinder is that fineness remains constant and stable in the case of wear of wearing parts.

Huatong ultrafine grinder is the only ultrafine grinding equipment with high cost performance that can achieve high fineness and continuous mass production in the field of ultrafine grinding in China.

It has solved the problems of adopting jet mill for making ultra-fine powder, such as high price, large power, more supporting facilities, difficulty in maintenance, low fineness for fiber materials including Traditional Chinese medicine, and low production. It has solved the problems of high energy consumption and high price of gas grinding to pulverize chemical materials and mineral materials.

It has solved the problem that mass production is unavailable for vibratory crusher.

With low-temperature crushing function, it can work 24 hours a day.

Continuous feeding and discharging ensures the color and efficacy of the materials, and prevent the loss of active ingredients. The machine can be operated independently or fully automated in the production line.

The main engine is designed with anti-clogging function to avoid crash.

(In case of material blockage in production, the blockage can be eliminated without stopping the machine.)

Due to the large number of materials, each part of the main machine is designed with a cleaning opening, which is easy to disassemble (assemble), replace materials, and clean. It can be cleaned and disinfected with water, compressed air and alcohol.

No sieve, no residue (all crushed, 100% utilization rate of materials), no circulation (powdered at one time, high efficiency), no vibration, small volume, no foundation, not fixed, easy to move, convenient to be put in the upstairs.

The crushing process is completely closed without dust pollution, making the operating environment clean and environmental friendly.

It is easy to operate and repair with low maintenance ratio. Only one person is needed for operation and maintenance, without the need of professional mechanical maintenance personnel.

It has long service life, no discarding period.

The machine is mainly used for lifting powder materials to avoid dust in the conveying process. It is easy to disassemble and clean, and can be equipped with packaging machine, mixing machine, mixer, bulking machine and other equipment that need automatic feeding. Vibration-assisted blanking can avoid bridging or residue of materials, which can realize the function of automatic feeding. It will stop if the materials are filled up, and feed automatically when no material is available, which is convenient for users to operate and reduce labor intensity. Spiral feeding machine with different diameters can be selected according to different lifting efficiency.

Low temperature chiller is a kind of water cooling equipment, which can provide constant temperature, constant current, constant pressure. The chiller works as follows: a certain amount of water is injected into the internal tank of the machine, and the water is cooled by the refrigeration system. Then the circulating pump inside the machine injects the cryogenic water into the equipment that needs to be cooled. The cryogenic water takes away the heat inside the equipment, and then the hot water flows into the tank again for cooling.

The rotary valve is important equipment in the pneumatic conveying and ventilation system. It is mainly used to continuously discharge the materials in the unloader or dedusting equipment, while ensuring that the pressure in the equipment is not exposed to the atmospheric environment. Because of its working characteristics, it is widely used in the powder process, feed, machinery, chemical industry, metallurgy, cement and other fields. It plays the role of continuous discharge and compaction for powder, granular, sheet and fiber materials under positive and negative pressure. The inlet and outlet (square or round) of the rotary valve are consistent in size, feeding from the upper part and discharging from the lower part. It can adapt to different installation occasions, with overall compact structure, which is easy to maintain.

If you have any suggestions or opinions about our products, please leave a message, and we will immediately answer your questions. Thanks for your support.